Once the job has been initiated, the bi-directional communication between the JobControl laser software and the laser allows you to change.

Send the field at low power (about 10-20 ), maximum speed and 500 dpi to the laser. 6%.The spot spatial uniformity decreases with increasing distance of deviating image surface,the spatial non-uniformity is up to 5% at 3mm place deviating image surface.Laser directly drives planar target with ablation layer, the effects of laser spatial uniformity on flyer planarity and integrity were investigated.The results show when the non-uniformity of laser is below 2%,the integrity of inference fringes measured by laser velocity interferometer system for reflector keeps very well,the inference frin-ges last about 20ns after fringes jump.And the flyer can fly about 150 microns.The roughness of discontinuity is 62ps,which indicates that the shock wave planarity is good.The target debris deposited on sputtering film from the target of about 120mm is larger particles,which confirms the flyer has better integrity.When the laser non-uniformity is 5%,the interference fringes dis-appear completely after fringes jump,and the target debris deposited on sputtering film becomes powder,which indicates the shock wave planarity is very poor under this laser condition.The experimental results show hydrodynamic instability seed is weak at good condition of the uni-formity of laser,the development of shock waves is not strong enough to make the flyer disinte-gration when shock waves transfer from the front surface to rear of larget.When the laser non-uniformity is about 5%,hydrodynamic instability seed driven by laser is very strong.When the shock wave transferred to the target back,hydrodynamic instability develops strong enough to make the flyer disintegration even gasification,which leads to the disappearance of interference fringes.So shock planarity driven by laser is strongly dependent on the laser beam spatial uni-formity,and the planarity and integrity of flyers depend on the shock planarity.According to the simulation results using one dimensional HYADES program,the ablation layer thickness should be reduced in order to improve the velocity of flyer.At the condition of thinner ablation layer,la-ser and ablation parameters do not match,shock waves driven by laser can accelerate the flyer multi-times.KrF laser with power density of about 1012 W/cm2 drove flat target of 5μm aluminum with 50μm Kapton ablation.Flyer trajectory was obtained using side-on shadowgraph.The curves of flyer velocity and acceleration were obtained by fitting the trajectory curve.Acceleration reaches 0.23×109km/s2,the velocity of flyer is about 9.8km/s.And the HYADES simulation shows there are 4 acceleration processes,the flyer velocity is about 10km/s.The results of experiment and simulation agreed very well.At the same conditions,simulations also show when the abla-tion thickness decreases to 30μm,the flyer velocity can be up to 16.5km/s.Target debris from backward jet maybe pollutes the laser focusing system components for too thin ablation.These all need to be verified by experiments. The size of the material will impact the size of the field as a standard size we recommend 1.97 x 1.97 in. The laser can only put out as much power as it is designed for. jumpspeed movement speed resulting out of movement of all axes during jumps (movements when. Speeds of 30 to 35 inches per second might be fine for removing anodize on aluminum, but engraving deeper into metals will be better accomplished at a speed of 5 inches per second, making multiple passes over the part.

LASER JUMP SPEED SERIES

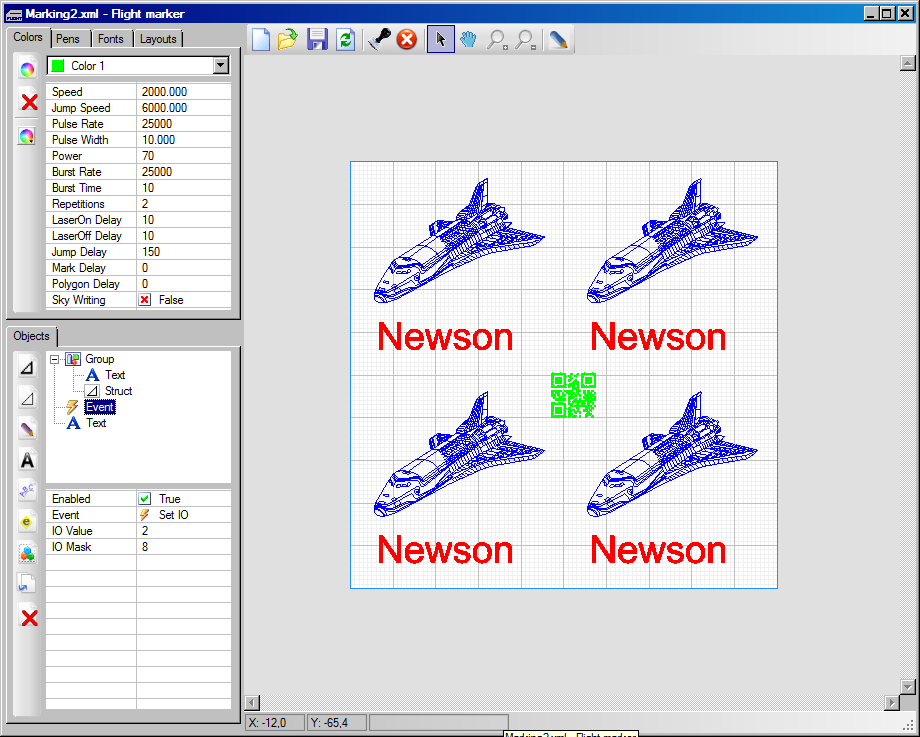

Furthermore, F series users can benefit from our latest innovative techniques contains laser cutting for laminate materials, impulse laser cutting for angel, frequency convert laser cutting technique and laser-power switch cutting.KrF excimer laser (248nm)has high spatial uniformity by using induced spatial in-coherence technology.After image relay and amplification by optical angular multiplexing tech-nology,non-uniformity of image surface of focal spot is 1. 10/2019 Wiring scheme for MaxPhotonics fiber laser added. Jump Speed is the speed at which the galvo mirrors move when not marking laser segments. We invest a lots in R&D of laser cutting techniques such as zero-second piercing, fly cutting, frog-jump, air cutting and many other techniques to reduce consumption and increase laser cutting efficiency.

LASER JUMP SPEED UPGRADE

The powerful CNC system and nesting software solves 100% difficulties for specific cutting and upgrade ahead of the precision and piercing speed during whole cutting process, and user-friendly.į Series has a maximum position speed up to 200m/min, the double acceleration can reach up to 2.8G. The latest cutting technique can also apply on non-ferrous metals includes aluminium & aluminium alloys, copper, brass, and zinc.

We have innovated our laser cutting technique during past 10 years, now the ultra-fast laser cutting technique has widely used in carbon steel, stainless steel and aluminum alloy. dynamic open loop method in which the controller uses the jump time look-up table to determine the time to wait before the next move.

0 kommentar(er)

0 kommentar(er)